Manufacturing units are more complex than anyone can anticipate. Number of machines, a larger number of labourers, and numerous tools has all to be accommodated. And then there exists a continuous need of effectively managing them for optimum utilization and better productivity. Additionally, there is always a pressure of up keeping the quality of the products, maintaining and exploiting the capacity of the plant to the fullest, following industry standards and good manufacturing practices, meeting compliance, and touching customer deadlines plus expectations amidst all these.

New Stuff: Sales History For all Costing Method

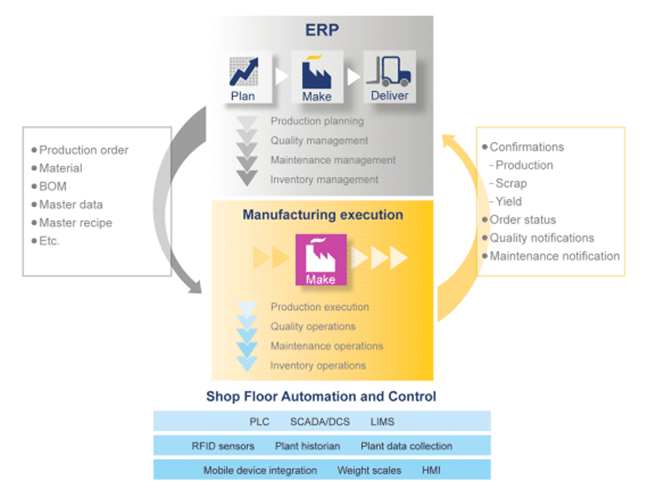

An ERP software can be a savior, supporting every manufacturing process and freeing-up more time and resources for businesses to invest in more profitable areas. Implementing ERP software brings together all the various operations of a manufacturing unit. ERP offers solution that enables manufacturers to compete in the prevailing market atmosphere. A good tailored ERP has the capacity of both finite and infinite planning capabilities. It transforms the supply chain to achieve production plan with your sales plan, manufacturing, finance and customers.

A number of benefits are realized by manufacturing units upon implementing an ERP, some of them are:

Better co-ordination along with Extensive Reflectivity

ERP brings together all departments and functions in a manufacturing unit and links them through a centralized database. Everyone from Production Manager, Inventory Manager, Shop-Floor Attender and QC Personnel gets the same version of the truth and also the real-time information.

Improved Efficiency

ERP is designed to automate and support elongated supply chains. Manual processes can be error-prone and time consuming. Employees may forget certain vital steps in the processing leading to inefficiency. But an ERP can standardize and accelerate procedures on every operation.

Better Quality

Enhanced quality is a major outcome of an ERP. It enables applying quality check at all points of the manufacturing.

Cost Reduction

Direct benefits of an ERP is reduced overheads and processing time. Not just this, proper planning through an ERP leads to optimum inventory level and reduced inventory means less wastage, cut-down on space, labour and maintenance costs.

Timely Deliveries

Better planning of material, demand and production ensures that components and raw materials are available, plan is set to meet the orders and production is laid out in time. Result: In-time deliveries. Better services. Happy customers. Greater profits.

A glimpse on benefits of ERP :-

• Minimise manufacturing cost and increase of resource utilisation

• Cut down production bottlenecks

• On-time delivery performance

• Transparent operational control

Nevertheless, advancing globalization and stronger competition demand manufacturing businesses in both discrete and process industry to have seamless process control, greater flexibility and cost efficiency provided effortlessly by a well-structured ERP.

We would soon discuss in detail about the different manufacturing models and ERP implications on them.

Also read:

1. Order Process for Manufacturing Company in Sage 300 ERP

2. Can ERP Implementation be ignored?

3. Be ERP Ready

4. Sage 300 ERP in Sugar Industry

5. BOM Setup for Manufacturing Company in Sage 300 ERP