In Sage X3, Work orders dictate what product need to be manufactured, what raw materials are going to be required to manufacture the product, and which work center that the product needs to pass through in the manufacturing process.

New Stuff:- Multiple ways to sign a standard workflow

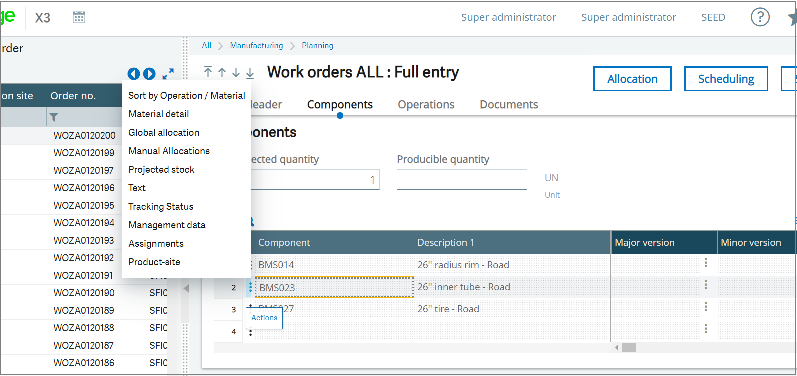

We have a Work Order created in Sage X3 and we are ready to start tracking it. We realize that there are some components on the Work Order that we will not be using. We decide to exclude those components, but for some reason the ‘Exclude Line’ option is not available.

Typically we would make sure that the Component we want to exclude is NOT allocated.

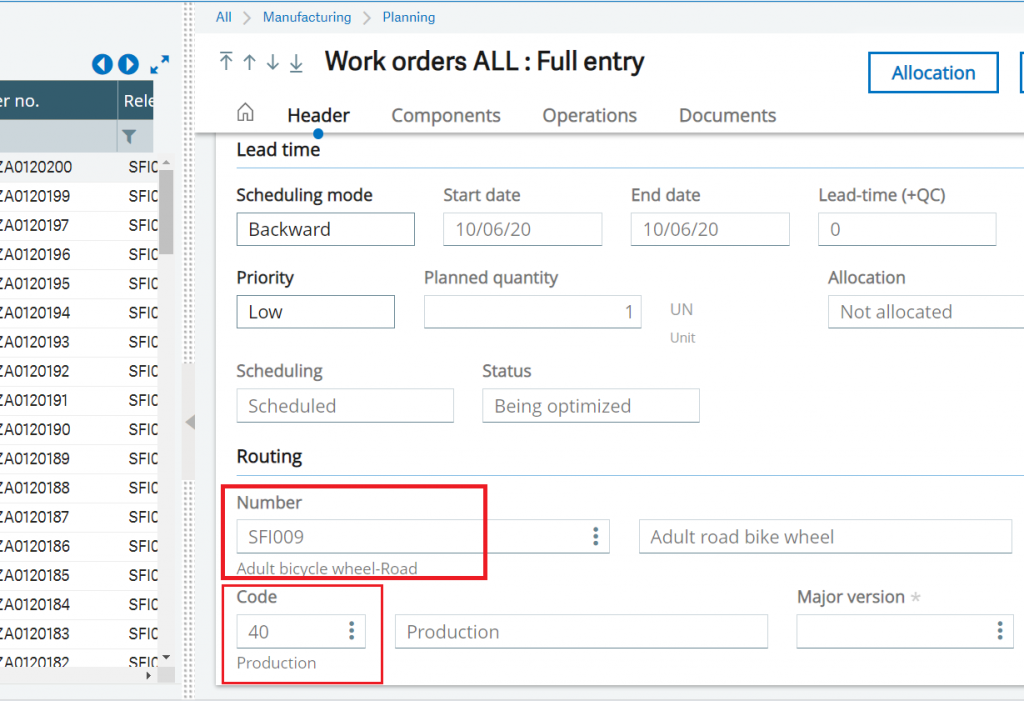

STEP 1: Check the Routing and Routing Code.

A routing is defined by a product code and a routing code.

The routings are used to describe the production processes of the finished products and sub-assemblies: they are made of a set of elementary operations that must be performed in an order set by scheduling. This function is used to create, view and update a routing information.

It is possible to have several routings for a single product reference, which are adapted to the use context: technical description of the R&D Department, cost calculation, macro-routings for the global costs calculation, etc.

It is possible to define routing codes: the routing code is a number associated with the product code, which identifies the routing code and authorizes the existence of several routings for a single product. The codes must be set up in the routing code table.

If you are sure that the component is not allocated, the reason that Exclude line is not showing is because of the set up on your Routing.

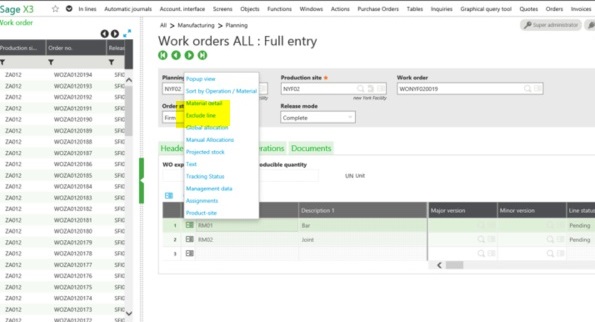

Highlighted below is the Routing and Routing Code used on this Work Order.

Here, Routing is ‘SFI001’ and Routing Code is ‘40’ and Site is ‘ZA012’.

STEP 2: Change the set up on your Routing.

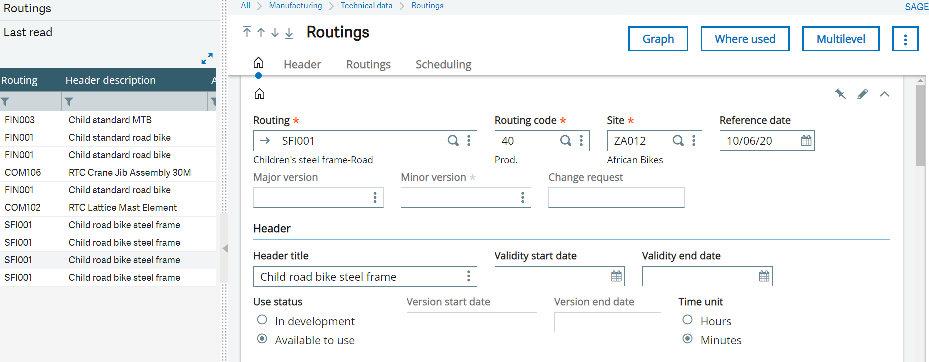

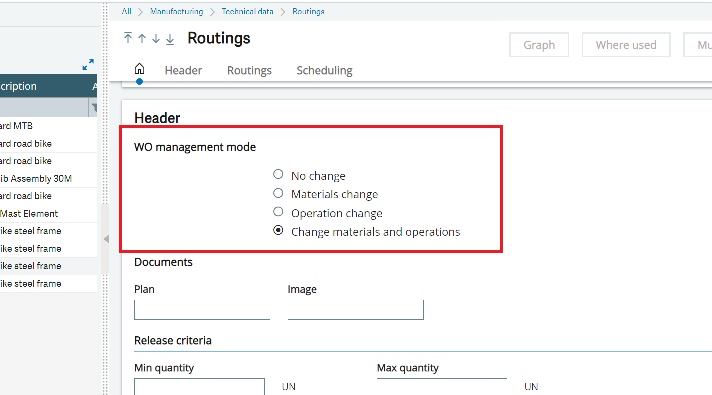

Navigate to: All -> Manufacturing -> Technical Data -> Routings -> Routing Management

Work order is used in the work order generation by using one or more BOMs and a single production routing.

Select our Routing with the correct Routing Code from the left list.

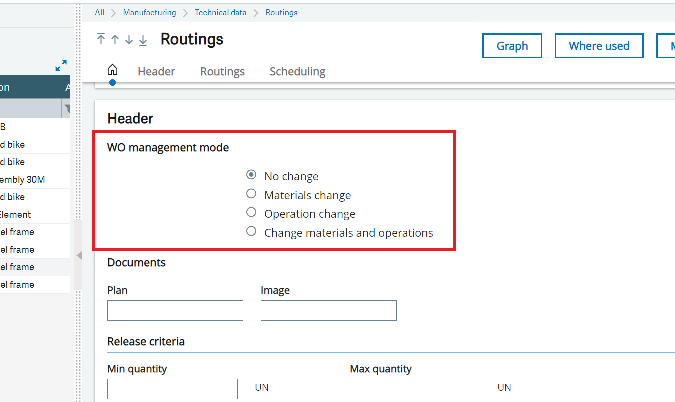

The WO management mode based on this routing and information concerning the last release.

We will notice that under the WO management mode either ‘No change’ or ‘Operation change’ is selected.

We need to change this to either ‘Materials Change’ or as in the example below ‘Change Materials and Operations’ and we need to save.

STEP 3: Check the Work Order:

Navigate to: All -> Manufacturing -> Planning -> Work order

We need to go back and check our Work Order, under components tab click on the action button. Now ‘Exclude line’ is available.

This blog helps to understand how to exclude components on a Work Order in Sage X3.