A BOM is an assembly, a finished product, made up of assemblies and components. If an assembly is used as a component of a final product it is referred to as a sub-assembly or semi-finished product. Each sub-assembly will itself have a list of components and this list can also contain sub-assemblies. Up to 999 levels of assembly can create below the final assembly.

New Stuff:- How to use service products in Purchasing

Sales (kit) BOMs are the commercial BOMs used on Sales Order.

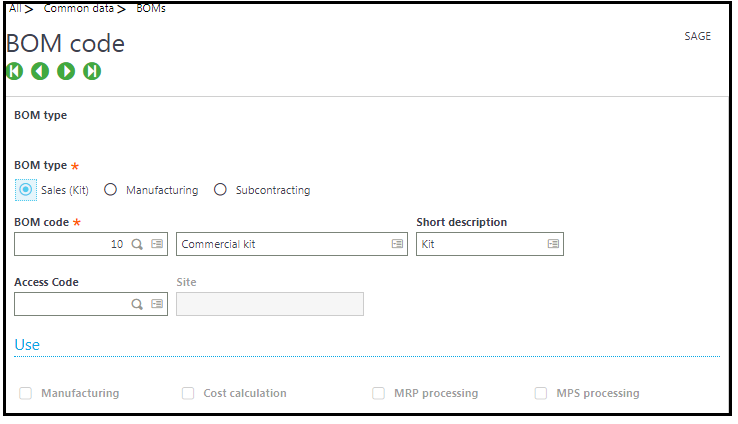

Why to create BOM Code:

BOM Types are

*Sales(KIT)

*Manufacturing

*Subcontracting

Create BOM Code and assign BOM code to one of BOM Type above and BOM code is used for all context as BOM Type.

For commercial BOMs select Sales (kit) as the BOM type

Navigational Path: Common Data>BOMs>BOM Code.

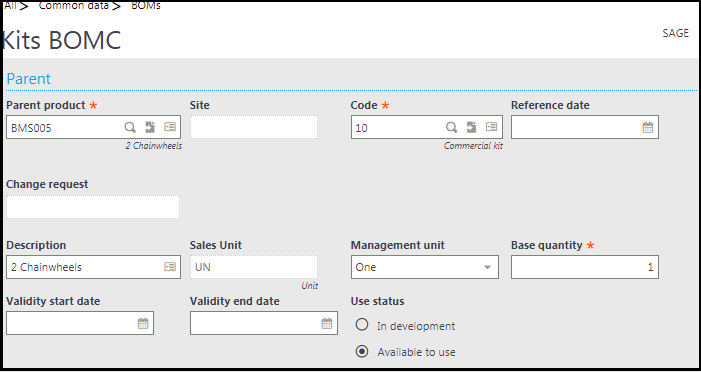

Create Commercial BOM

Navigational Path: Common Data>BOMs>Commercial BOM.

Site: If the site is blank, it can be used at all sites

– Code: Enter the BOM code created. Multiple BOMs can be defined for a single product.

– Reference date: It is assigned when we create the record and it can be modified. It cannot be blank.

– Management unit: Use this field to define how the quantities of the components needed to make this parent product. Percentage is not available for commercial BOM.

– Use status: ‘In development’ meaning the components that make up the product are being defined. ‘Available to use’ the structure of the BOM is complete and has been validated.

Select the components:

Components:

– Sequence number: A single component can exist multiple times in a BOM by assigning a different sequence number for each instance of the component.

– Link quantity: Use this field to define the quantity of this component in the displayed unit that is needed to make the parent product.

– Component type: There are several component types that we can use on a sales/ commercial BOM.

*Normal – standard component and always added to a sales transaction.

*Option – an optional component and it is not mandatory to add it to a sales transaction.

*Variant – a variant or alternative of a standard component. It is mandatory to add the standard/ variant component to a sales transaction.

*Multiple option – When a value must be calculated for the provisional cost and the production cost price of the parent product.

*Normal (with formula) – This is the default value if we are using a selection formula. Components selected by the formula are standard components of this BOM and added to a sales transaction.

Note: All components with the same sequence number must have the same component type.

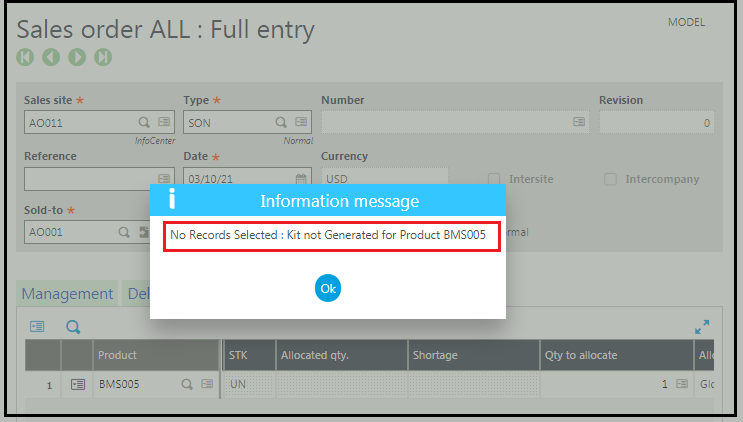

Error: “No Records Selected :Kit not generated for the product” on sales order

Solution for solving “No Records Selected : Kit not generated for the product” on sales order.

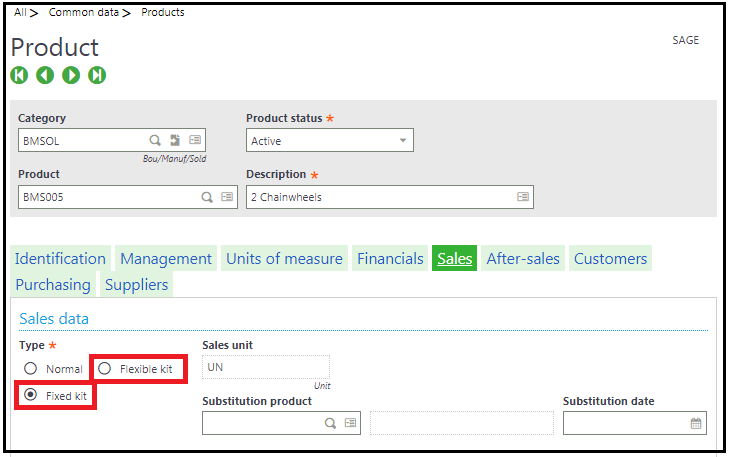

Check Product Master Sales Data Type

Navigational Path: Common Data > Products > Products

Sales tab –check the box ‘Fixed Kit’ or ‘Flexible Kit’

The main difference between the fixed kit and the flexible kit is that in a flexible kit, we can delete products from the BOM as required but in a fixed kit, we cannot delete products from the BOM.

When a product is defined as a KIT then it must have Commercial BOM set up for the product.

Change the Product Record by un-checking ‘Fixed Kit’ or ‘Flexible Kit’, check ‘Normal’ and save

Or by creating Commercial BOM for the Product on sales order

This blog helps us to understand what is commercial BOM and how to create BOM code for BOM type and how BOM code is replicating BOM type for commercial BOM and difference between flexible kit and fixed kit of sales data type on product master. Solution for the error “No Record Selected -Kit not generated for the product”

About Us

Greytrix – a globally recognized and one of the oldest Sage Development Partners is a one-stop solution provider for Sage ERP and Sage CRM organizational needs. Being acknowledged and rewarded for multi-man years of experience and expertise, we bring complete end-to-end assistance for your technical consultations, product customizations, data migration, system integrations, third-party add-on development, and implementation competence.

Greytrix has some unique integration solutions developed for Sage CRM with Sage ERPs namely Sage X3, Sage Intacct, Sage 100, Sage 500, and Sage 300. We also offer best-in-class Sage ERP and Sage CRM customization and development services to Business Partners, End Users, and Sage PSG worldwide. Greytrix helps in the migration of Sage CRM from Salesforce | ACT! | SalesLogix | Goldmine | Sugar CRM | Maximizer. Our Sage CRM Product Suite includes addons like Greytrix Business Manager, Sage CRM Project Manager, Sage CRM Resource Planner, Sage CRM Contract Manager, Sage CRM Event Manager, Sage CRM Budget Planner, Gmail Integration, Sage CRM Mobile Service Signature, Sage CRM CTI Framework.

Greytrix is a recognized Sage Champion Partner for GUMU™ Sage X3 – Sage CRM integration listed on Sage Marketplace and Sage CRM – Sage Intacct integration listed on Sage Intacct Marketplace. The GUMU™ Cloud framework by Greytrix forms the backbone of cloud integrations that are managed in real-time for the processing and execution of application programs at the click of a button.

For more information on our integration solutions, please contact us at sage@greytrix.com. We will be glad to assist you.