Recently there was a requirement to flow the work center and it’s description from work center screen to Load WIP inquiry screen in Sage X3.

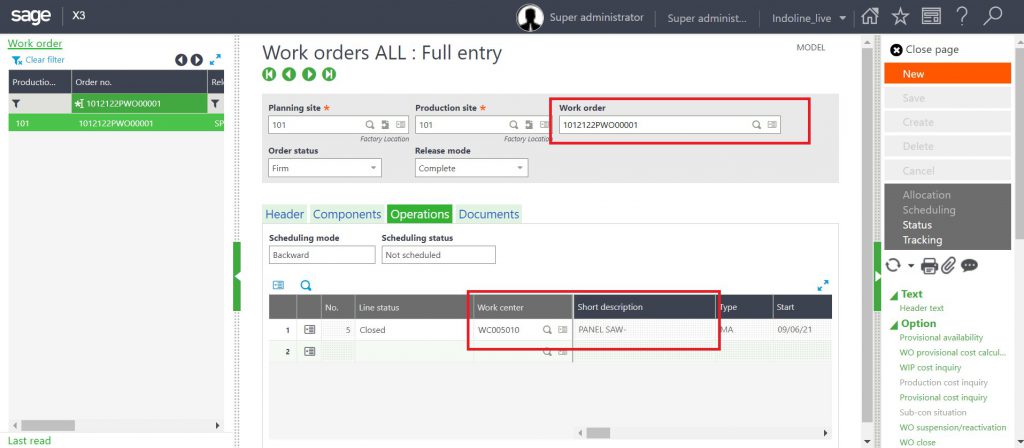

Navigate: Manufacturing -> Planning -> Work Order -> Operations

New Stuff: How to control the Scrap percentage while we make the Production tracking in Sage X3

Initially we have created new work order entry from the Manufacturing module and in the Header tab, we have selected the FG product and entered the quantity. Then components which are required for that FG product and work center are getting flown automatically in the Components and Operation tabs respectively.

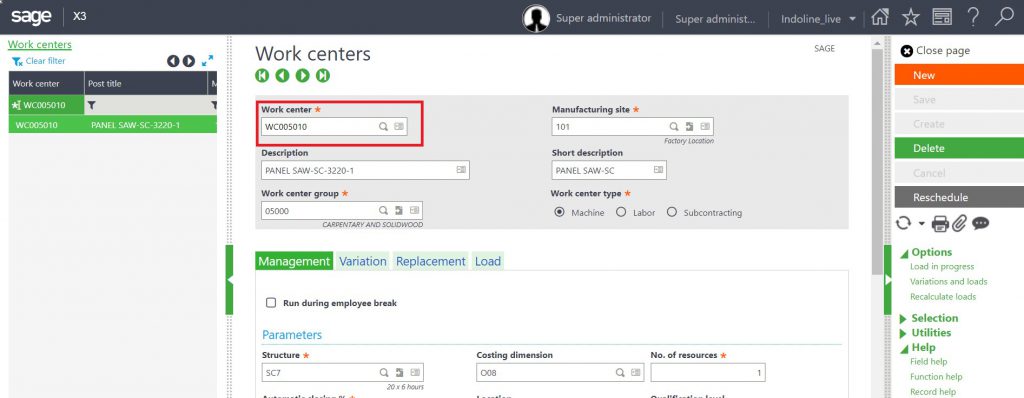

Navigate: Manufacturing -> Technical data -> work center

After that in Work Center master, create a new work center and add description for that work center then , select the work center type and work center group as shown in the above screen shot, and click on the create button. New work center will be created. Add same work center for the FG Product in BOM screen. So that while creating work order, the same work center will be flown in the work order screen.

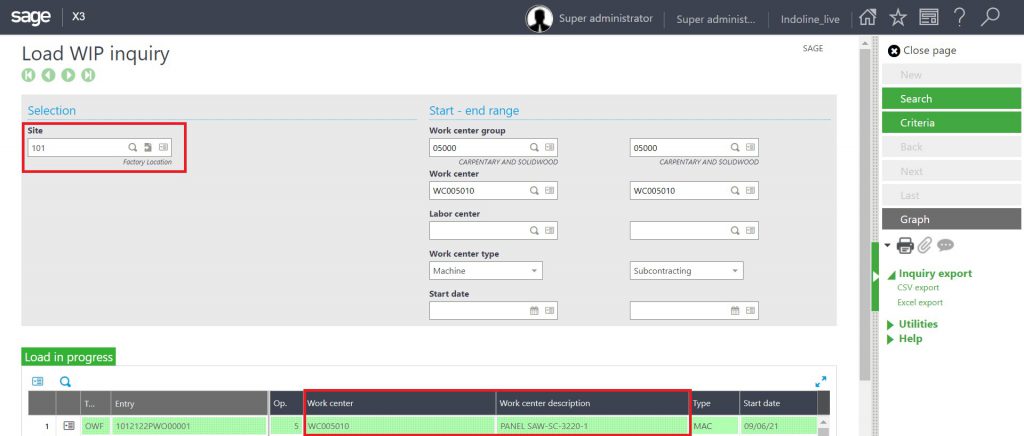

Navigate: Manufacturing -> Inquiries -> WIP -> Load in progress

Select the Manufacturing site, Work center group, Work center and Work center type in filter criteria. Click on the search button, the work center description will be flown from the Work Center to Load Inquiry screen as shown in the above screenshot.

In this way, we have flown the work center and it’s description from work center screen to Load WIP inquiry screen in sage X3.