This function is used to calculate the budgeted cost of one or a range of products at a specified site. This function is typically used to prepare provisional costs for the following year. Costs are calculated from a set of user-defined parameters.

A single product-site record has only one budget cost. You can prepare simulated costs then update the product-costs records when the costs are finalized. Costs are established from routing data (time) and valuation dimension data for work centers associated with a route on a specified calculation date.

Material cost selection field determines how material costs are calculated. The valuation method, if defined on the products-sites record, is considered. Price lists are also considered. The cost of subcontract materials is from a price list; if the price list is not found, the standard cost can be used if the PURPRICE – Price by default standard cost parameter (ACH chapter, PRI group) is set to ‘Yes’.

If a product has a BOM, the production overhead is taken into account, otherwise the receipt overhead is taken into account.

Navigation

All>>Costing>> Budgeted cost calculation

Steps and Parameters

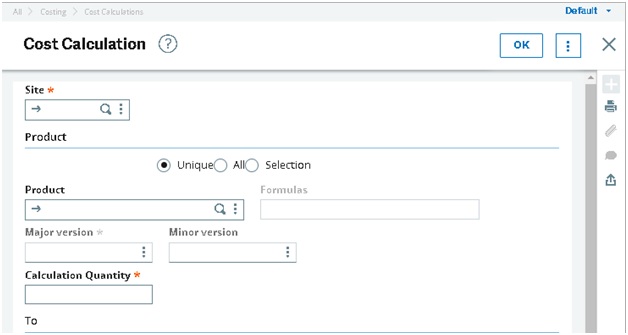

Below are the parameters required for Budgeted cost calculation,

- Product. This field is only required if you click (select) the Unique radio button.

- Formula. This field is only required if you click the Selection radio button. You can use a filter calculation expression formula to select the products to be included in the calculation run or apply a filter.

- Calculation quantity. The quantity to be included in the calculations. This field is only available if a product code has been defined. The default quantity is the Economic order quantity (field EOQ (REOMINQTY)) defined on the product-site record or the Technical lot (field MFGLOTQTY) defined on the product-site record, or 1. Use the Validity section to specify your run time parameters:

- Fiscal year. A calculation run for a combination of ‘Site’ + ‘Product’ + ‘Fiscal year’ that has been run previously overwrites the previous calculation if the selected type of update is ‘Deferred’ or ‘Immediate’ (field Update (field MAJ)).

- Routing code. If you leave this field blank only material costs are calculated.

- BOM code. The default BOM alternative displayed is the first BOM alternative associated with the selected routing alternative (field Routing code (field ROUALT)).

- Calculate all BOM levels. This check box is only available if this calculation run is for a single product (the Unique radio button is selected). If selected, the cost calculation process will descend through the bill of materials (BOM) to the lowest level, or up to a parent product whose ‘Standard cost update’ in their product-site record is entered.

- Fixed costs distribution. The fixed overhead costs (material loss, setup rate, operation loss rate, fixed rate) can be distributed as a total sum or spread pro rata from the combination of the calculation quantity/economic lot quantity.

- Material cost. Used for the calculation of material costs. The default cost type is defined in the CLCBUDMAT-Mat cost selection bud calc parameter (TC chapter, COS group).

- Dimension rate. Used for the calculation of labor and machines. The default cost type is defined in the CLCBUDRAT-Dimension rate selection bud C parameter (GPA chapter, COS group).

- Overhead column. Used for the calculation of overheads. The value of an overhead is calculated by applying the fixed rate or the formula in the chosen calculation column.

About Us

Greytrix – a globally recognized and one of the oldest Sage Development Partners is a one-stop solution provider for Sage ERP and Sage CRM organizational needs. Being acknowledged and rewarded for multi-man years of experience and expertise, we bring complete end-to-end assistance for your technical consultations, product customizations, data migration, system integrations, third-party add-on development, and implementation competence.

Greytrix has some unique integration solutions developed for Sage CRM with Sage ERPs namely Sage X3, Sage Intacct, Sage 100, Sage 500, and Sage 300. We also offer best-in-class Sage ERP and Sage CRM customization and development services to Business Partners, End Users, and Sage PSG worldwide. Greytrix helps in the migration of Sage CRM from Salesforce | ACT! | SalesLogix | Goldmine | Sugar CRM | Maximizer. Our Sage CRM Product Suite includes addons like Greytrix Business Manager, Sage CRM Project Manager, Sage CRM Resource Planner, Sage CRM Contract Manager, Sage CRM Event Manager, Sage CRM Budget Planner, Gmail Integration, Sage CRM Mobile Service Signature, Sage CRM CTI Framework.

Greytrix is a recognized Sage Champion Partner for GUMU™ Sage X3 – Sage CRM integration listed on Sage Marketplace and Sage CRM – Sage Intacct integration listed on Sage Intacct Marketplace. The GUMU™ Cloud framework by Greytrix forms the backbone of cloud integrations that are managed in real-time for the processing and execution of application programs at the click of a button.

For more information on our integration solutions, please contact us at sage@greytrix.com. We will be glad to assist you.