In Sage X3, for the entry of documents requiring analytical dimensions, a default dimensions function specifies how to enter these dimensions by default. Strictly speaking, they are not accounting documents (most of them are generated outside the Financials module), but they can generate postings. These setups are useful to enter the analytical allocations in all the movements where they are stored.

The main principle is to define for each dimension type an order of priority when searching a default dimension, by providing a list of tables where to search for these dimensions.

E.g.:

To enter the order lines and for a given dimension type, it is possible to specify that the default value be searched in the product record, then (if the field is not assigned at this level) in the customer record and then, by default, in the order header. Later one, the places (usually tables) where the dimensions can be searched are referred to as Identifiers.

The identifiers that can be used are the following: Product, Customer, Supplier, Sales executive, Buyer, Fixed asset, Bank, Company, Site, Currency, Tax, Payment, Journal (it is the header of the journal being entered, and which can be used to initialize the lines), Sales footer, early discount, Account, Miscellaneous BP, Valuation dimensions, Overheads, Original document, Previous dimensions.

Here, we will discuss about the dimesion that are used in Manufacturing whether creating a work order manually or automatically, creating the production, closing, and costing the work order.

The three default dimensions for standard work order are:

MFI: Released products

MFO: Operations

MFM: Components

If the work order is automatically created within the plans (Enterprise planning, Planning workbench, Grouping), the default dimensions are:

MFIAUT: Auto Released products

MFOAUT: Auto Operations

MFMAUT: Auto Components

When a production tracking is manually created, these are the dimensions used:

MKI: Tracking of released products

MKO: Operations tracking (principal work center)

MKOLAB: Operations tracking (secondary work center)

MKM: Material tracking

When tracking is created using a Time tracking plan, the dimensions are:

MKIAUT: Auto tracking of released products

MKOB: Auto operations tracking (principal work center)

MKOLABB: Auto operations tracking (secondary work center)

MKMAUT: Auto material tracking

When using the Production plan to create a tracking, the dimensions are:

MKIB: Released products tracking plan and MKMAUT: Auto material tracking.

If using a Material tracking plan, the used default is MKMB: Material tracking plan.

When the work order is completed and closed, these are the dimensions used:

MKOAUT: Auto operations tracking (Principal WC)

MKOLABAUT: Auto operations tracking (Secondary WC)

MKMAUT: Auto material tracking

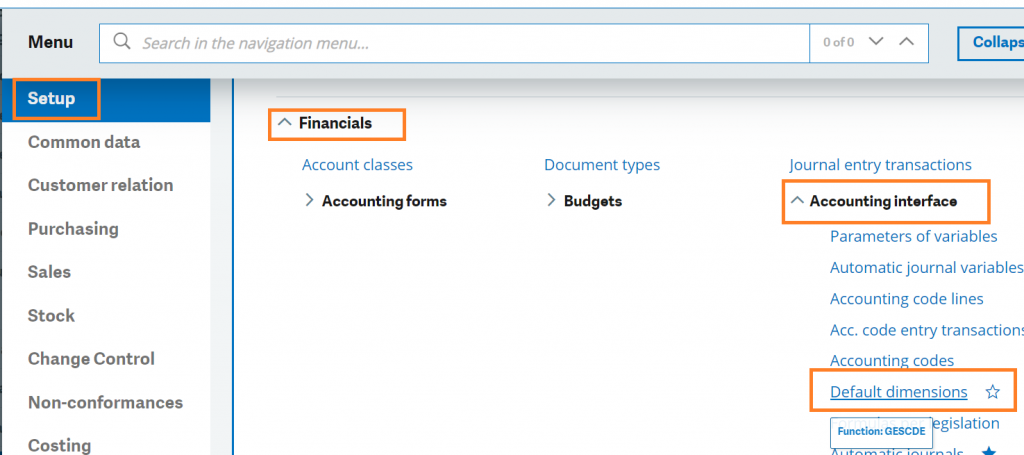

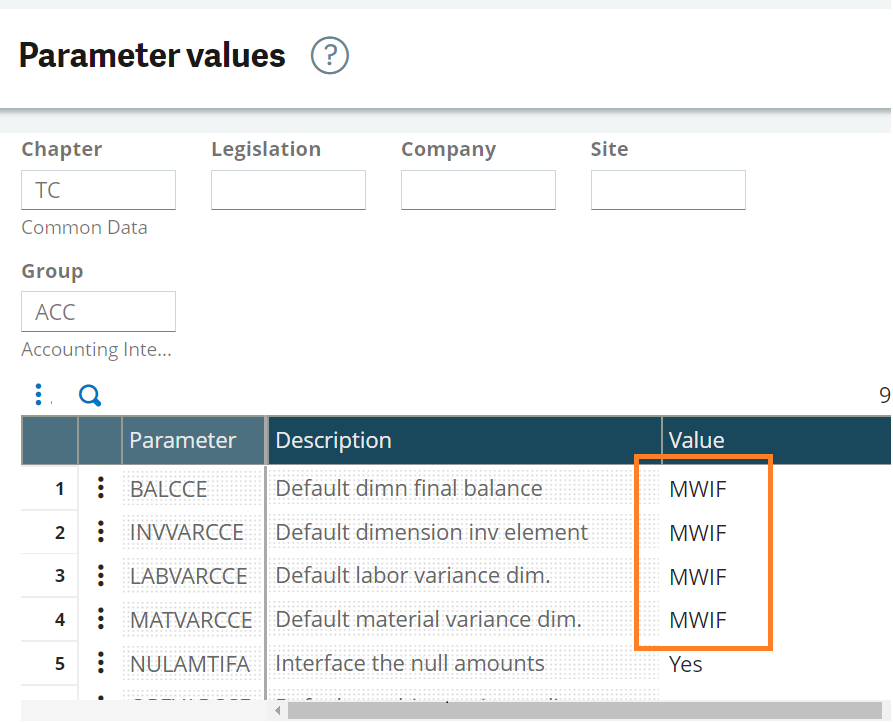

Finally, when the work order is costed, MWIF: Balance/Close Works Order variance default dimension is used in Parameter values, TC common data, Accounting Interface.

This blog helps to understand what are the default dimensions associated with manufacturing in Sage X3.

About Us

Greytrix – a globally recognized and one of the oldest Sage Development Partners is a one-stop solution provider for Sage ERP and Sage CRM organizational needs. Being acknowledged and rewarded for multi-man years of experience and expertise, we bring complete end-to-end assistance for your technical consultations, product customizations, data migration, system integrations, third-party add-on development, and implementation competence.

Greytrix has some unique integration solutions developed for Sage CRM with Sage ERPs namely Sage X3, Sage Intacct, Sage 100, Sage 500, and Sage 300. We also offer best-in-class Sage ERP and Sage CRM customization and development services to Business Partners, End Users, and Sage PSG worldwide. Greytrix helps in the migration of Sage CRM from Salesforce | ACT! | SalesLogix | Goldmine | Sugar CRM | Maximizer. Our Sage CRM Product Suite includes addons like Greytrix Business Manager, Sage CRM Project Manager, Sage CRM Resource Planner, Sage CRM Contract Manager, Sage CRM Event Manager, Sage CRM Budget Planner, Gmail Integration, Sage CRM Mobile Service Signature, Sage CRM CTI Framework.

Greytrix is a recognized Sage Champion Partner for GUMU™ Sage X3 – Sage CRM integration listed on Sage Marketplace and Sage CRM – Sage Intacct integration listed on Sage Intacct Marketplace. The GUMU™ Cloud framework by Greytrix forms the backbone of cloud integrations that are managed in real-time for the processing and execution of application programs at the click of a button.

For more information on our integration solutions, please contact us at sage@greytrix.com. We will be glad to assist you.